1914 Apperson Jackrabbit Wooldridge Family History

| Home | Trip | Pictures | Links | Comments |

I am always looking for any information or parts for 1914 Apperson Jackrabbit.

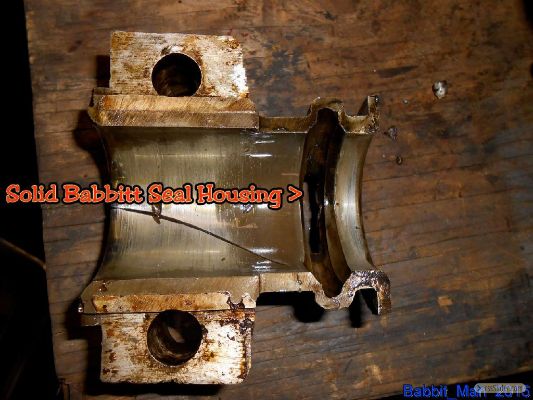

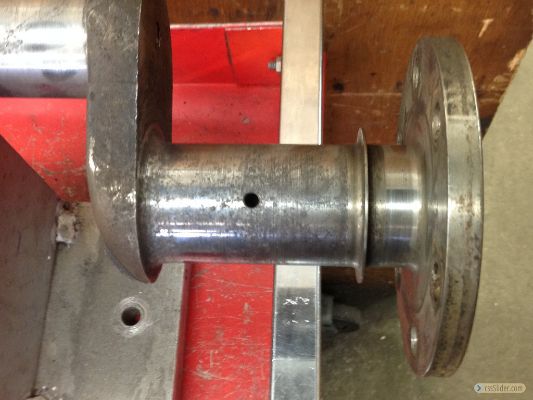

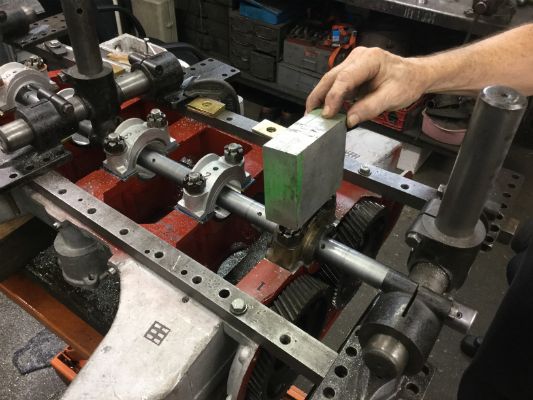

These are a few pictures of the Apperson engine removal and tear down. Also pictures of the parts I either had to repair or have made.

The Apperson engine was in worst shape than I though so it is good I am rebuilding it now. If I had waited the next failure could have ruined the engine beyond repair.

I am updating all seals from felt to modern type so I should not have as many leaks as before.

Click on picture for large view. Close window - tab to return.